Key Feature Serial Port Logger

Serial Port Logger provides users with these key features:

- Monitoring and logging serial port activity for troubleshooting and data analysis;

- Simultaneously monitoring multiple ports in real time;

- Support for physical and virtual serial ports;

- Table, line, dump, and terminal data views;

- Exporting session logs with filters and timestamps;

- Display data in Hex or ASCII mode;

- Emulate serial data commands for device testing.

Using Serial Port Logger

Teams leverage a serial data logger in the following common usage scenarios.

Logging and monitoring serial port activity and data flow

Serial Port Logger’s intuitive interface makes it easy to log and monitor COM port activity. Users select a serial port for monitoring, choose where to save activity logs, configure the COM port parameters, and click the "Start" button. All serial communication for the designated port is recorded in a text file, which can be stored for later use.

Monitoring and analyzing serial data transmission

The RS232 port logger lets teams monitor and analyze serial communication. This functionality benefits teams trying to understand serial port operation and data flow. A serial data logger team can precisely track and analyze port activity to identify and resolve performance or connectivity issues.

Test serial device and application communication

Free Serial Port Logger supports virtual environments like Virtual PC and VMware. This feature makes the tool an excellent choice for software development and testing. Students can use the software in an educational setting for hands-on learning about serial communication.

Serial Data Logger Usage Guide

After configuring the RS232 data logger software setting, you are ready to use it to monitor the serial port traffic on your system. The following steps outline the process.

1. Download and install the serial data logger program and start the application.

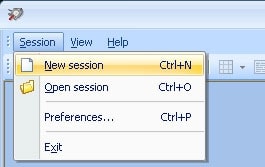

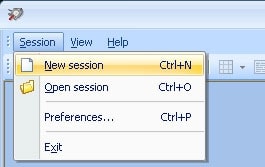

Select the “Session >>> New session” option from the app’s main menu. You can also click “New” on the main toolbar or use the CTRL+N shortcut when starting a session.

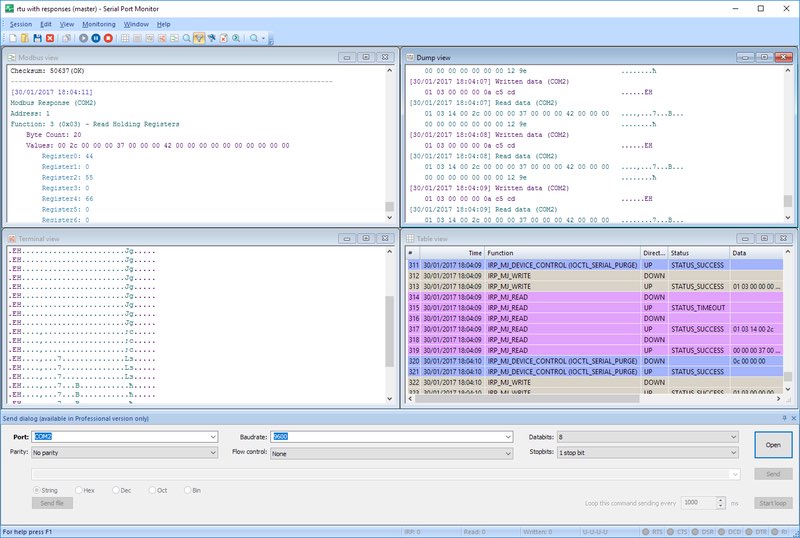

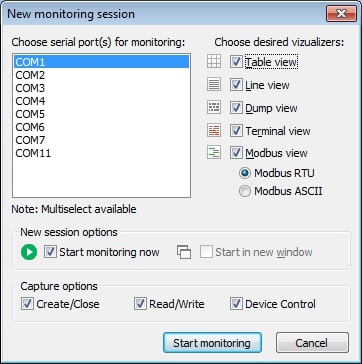

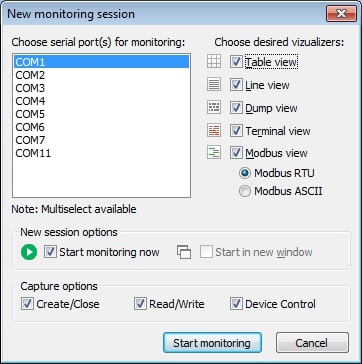

3. You will be presented with the “New monitoring session” window.

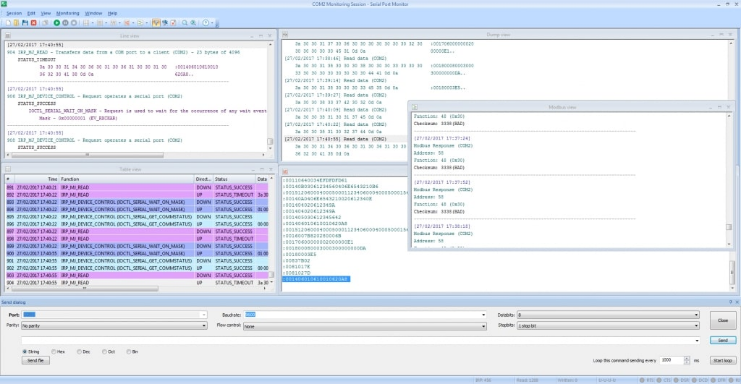

This is where you can select which visualizers are used for the session. They control how the data is displayed. You can choose any number of visualizers by checking the box to the left of its name.

- Table view uses a table format to display recorded IRPs.

- Line view provides detailed data transfer information regarding a designated serial line.

- Dump view shows all of the data that was sent and received through a serial line.

- Terminal view displays data transfer information on a console in ASCII format.

- Modbus view displays any Modbus data (RTU and ASCII) sent or received in the session.

Characteristics of a new monitoring system are set by selecting either the “Start monitoring now” or “Start in new window” checkboxes.

You can control which events will be monitored during the session by selecting Read/Write, Create/Close or Device Control.

4. Click “Start monitoring” when you are finished tailoring the settings to begin the new session.

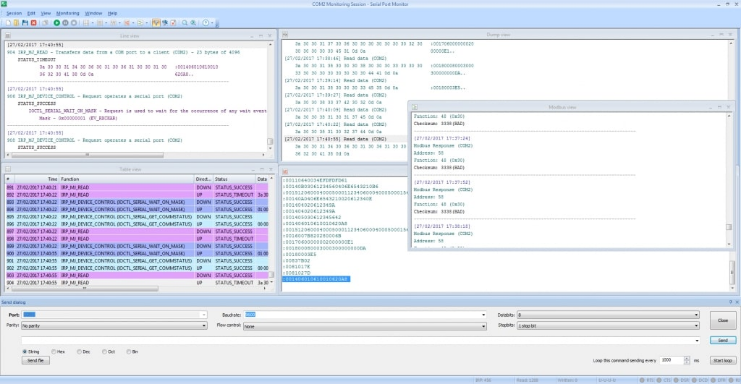

The program will open a new monitoring window which will present the serial data in the formats chosen when selecting visualizers.

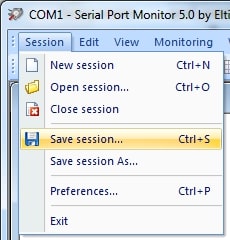

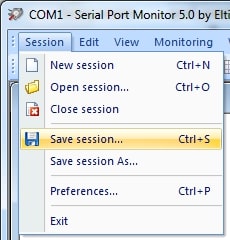

5. Sessions can be saved by selecting the “Session -> Save session/Save session As” option on the main menu. Alternately, you can use the CTRL+S keyboard shortcut or choose the “Save” button located on the main toolbar.